Tap Without Trouble: A Practical Guide to Adjusting Tap Drill Diameters for Different Materials

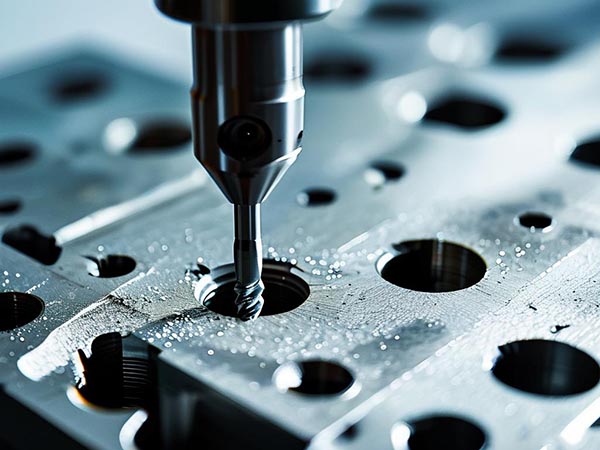

In precision machining, the quality of tapping directly affects the service life and assembly accuracy of components. Among the many influencing factors, adjusting the tap drill diameter is often the key to success. Material-specific characteristics—like the elastic recovery of aluminum alloys or the thermal expansion and adhesion of stainless steel—render standard parameters unreliable. This guide, grounded in material science and cross-industry data, systematically breaks down the adjustment logic for 16 common materials. It aligns global standards (including ANSI, DIN, and ISO), introduces compensation strategies for part thickness, and offers machine compatibility tips to help operators achieve the optimal balance between performance and cost.

| Thread Spec | ISO Drill Ø | ASME Drill Ø | DIN Drill Ø | Typical Use |

|---|---|---|---|---|

| M6×1 | Ø5.0 mm | Ø5.05 mm | Ø4.95 mm | Automotive engine components |

| 1/4"-20 | Ø5.1 mm | Ø5.15 mm | - | Hydraulic piping |

| M8×1.25 | Ø6.8 mm | Ø6.75 mm | Ø6.7 mm | Machine tool guides |

Industry Insight: German clients often request drill diameters 0.02 mm smaller to improve thread strength.

Industry Insight: German clients often request drill diameters 0.02 mm smaller to improve thread strength.

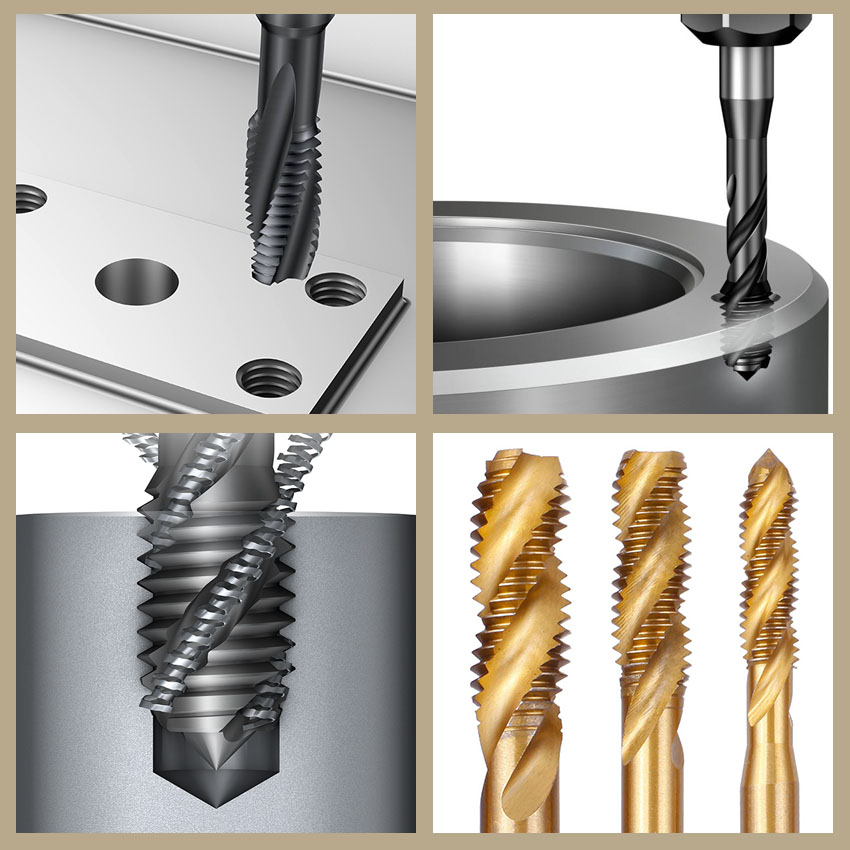

| Material Type | Example Part | Enlargement Over Standard | Recommended Tap Type |

|---|---|---|---|

| Aluminum Alloy | Enclosures / Heat sinks | +0.05 mm | Spiral-flute HSS tap |

| 304 Stainless Steel | Flanges / Valves | +0.03 mm | Cobalt HSS-E tap |

| Medium Carbon Steel | Gears / Shafts | No adjustment | Carbide tap |

| Brass | Plumbing parts | +0.07 mm | Straight-flute HSS tap |

| Workpiece Thickness | Adjustment Strategy | Recommended Tap Type |

|---|---|---|

| < 3 mm | Drill +0.05 mm | HSS-E for thin plate |

| 3–8 mm | Standard values | Universal carbide series |

| > 8 mm | Drill –0.03 mm | Deep-hole spiral tap |

Real-World Lesson: A customer failed to adjust for 12 mm thick aluminum, resulting in thread root fracture.

Real-World Lesson: A customer failed to adjust for 12 mm thick aluminum, resulting in thread root fracture.

Tapping is a delicate balancing act between material behavior, tool capability, and process conditions. From pre-enlarged holes for aluminum to step-cooling for stainless steel, each material demands tailored pre-tap strategies. Variables such as part thickness and machine type must also be factored into the correction model. With comparative global standards, thickness compensation tables, and chip morphology diagnostics, this guide builds a complete workflow—from drilling prep to final inspection. Whether dealing with thin-walled EV motor parts or precision threads in orthopedic implants, mastering the underlying principles and applying parameter adjustments flexibly ensures stable, high-efficiency threading.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.