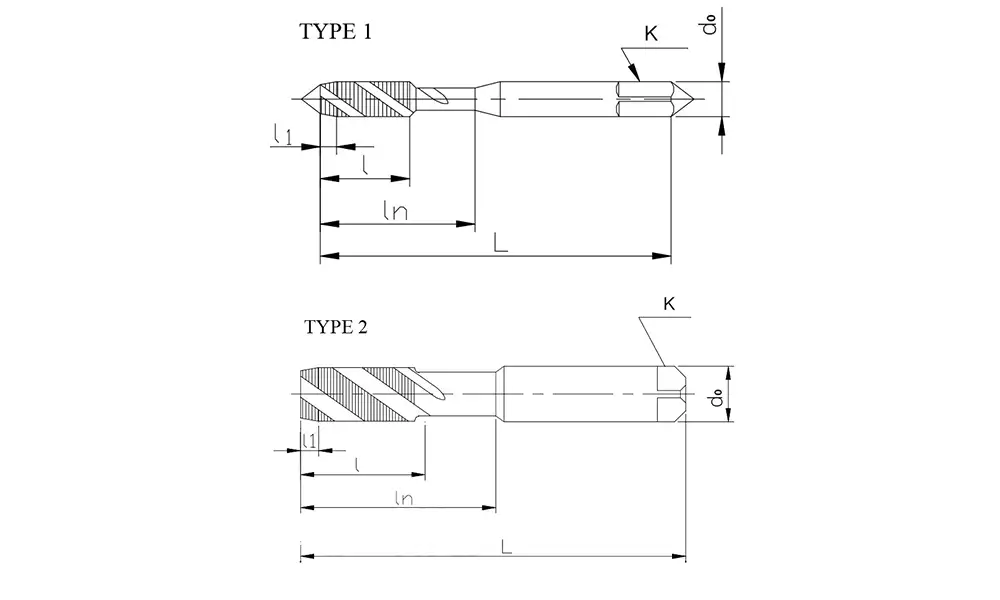

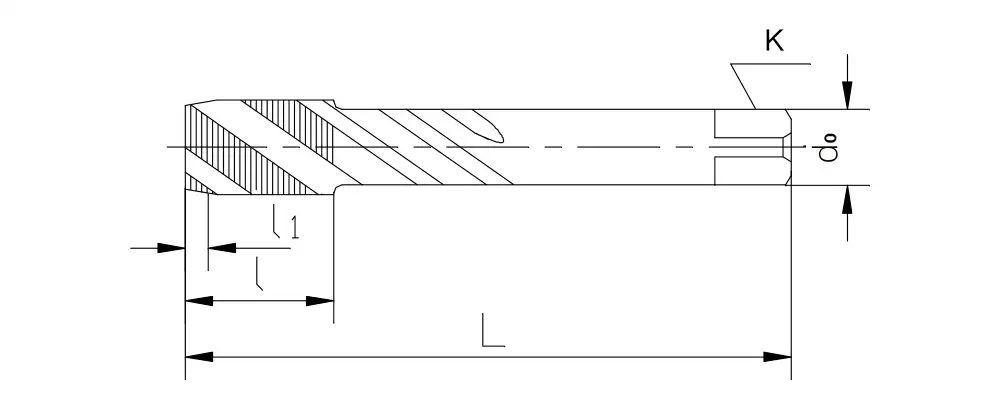

| Thread Size | TYPE | Pitch | L Overall length |

l Thread Length |

l1 Cutting Length |

ln Length to neck |

d₀ Shank diameter |

K Square size |

FLUTES |

| M3 | 1 | 0.35/0.5 | 48 | 11 | 2.5P | 16.5 | 3.15 | 2.5 | 3 |

| M3.5 | 1 | 0.35/0.6 | 50 | 13 | 2.5P | 18.5 | 3.55 | 2.8 | 3 |

| M4 | 1 | 0.5/0.7 | 53 | 13 | 2.5P | 19.5 | 4.0 | 3.15 | 3 |

| M4.5 | 1 | 0.5/0.75 | 53 | 13 | 2.5P | 19.5 | 4.5 | 3.55 | 3 |

| M5 | 1 | 0.5/0.8 | 58 | 16 | 2.5P | 23.5 | 5.0 | 4.0 | 3 |

| M5.5 | 1 | 0.5 | 62 | 17 | 2.5P | 23.5 | 5.6 | 4.5 | 3 |

| M6 | 1 | 0.5/0.75/1.0 | 66 | 19 | 2.5P | 29 | 6.3 | 5.0 | 3 |

| M7 | 2 | 0.75/1.0 | 66 | 19 | 2.5P | 30 | 7.1 | 5.6 | 3 |

| M8 | 2 | 0.5/0.75 | 66 | 19 | 2.5P | 32 | 8.0 | 6.3 | 3 |

| M8 | 2 | 1.0/1.25 | 72 | 22 | 2.5P | 35 | 8.0 | 6.3 | 3 |

| M9 | 2 | 0.75 | 66 | 19 | 2.5P | 33 | 9.0 | 7.1 | 3 |

| M9 | 2 | 1.0/1.25 | 72 | 22 | 2.5P | 36 | 9.0 | 7.1 | 3 |

| M10 | 2 | 0.75 | 73 | 20 | 2.5P | 35 | 10.0 | 8.0 | 3 |

| M10 | 2 | 1.0/1.25/1.5 | 80 | 24 | 2.5P | 39 | 10.0 | 8.0 | 3 |

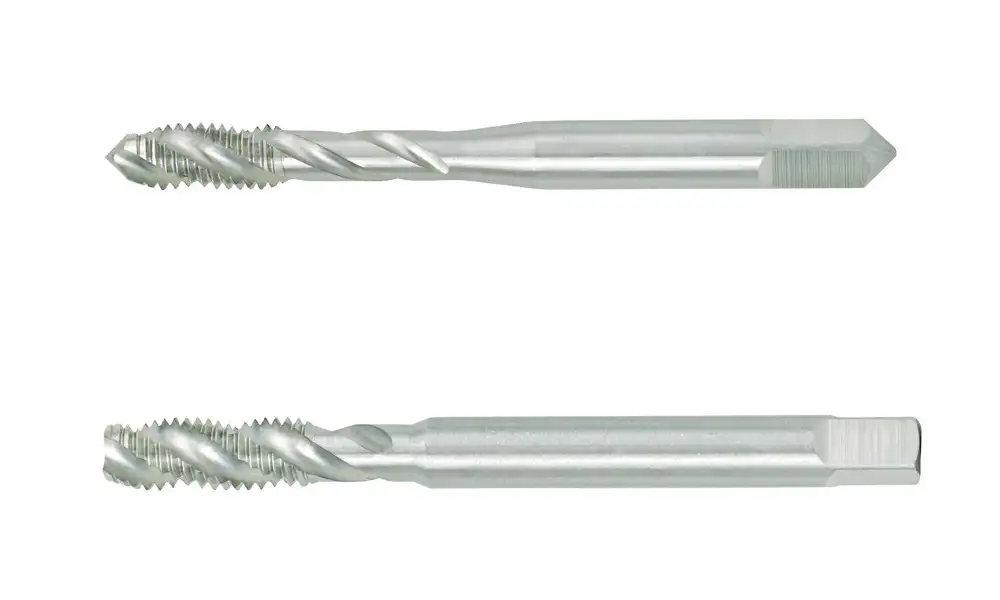

| Thread Size | Pitch | L Overall length |

l Thread Length |

l1 Cutting Length |

d₀ Shank diameter |

K Square size |

FLUTES |

| M7 | 0.75/1.0 | 66 | 19 | 2.5P | 5.6 | 4.5 | 3 |

| M8 | 1.0/1.25 | 72 | 22 | 2.5P | 6.3 | 5.0 | 3 |

| M9 | 1.0/1.25 | 72 | 22 | 2.5P | 7.1 | 5.6 | 3 |

| M10 | 1.0/1.25/1.5 | 80 | 24 | 2.5P | 8.0 | 6.3 | 3 |

| M11 | 1.5 | 85 | 25 | 2.5P | 8.0 | 6.3 | 3 |

| M12 | 1.25/1.5/1.75 | 89 | 29 | 2.5P | 9.0 | 7.1 | 3 |

| M14 | 1.25/1.5/2.0 | 95 | 30 | 2.5P | 11.2 | 9.0 | 3/4 |

| M15 | 1.5 | 95 | 30 | 2.5P | 11.2 | 9.0 | 3/4 |

| M16 | 1.5/2.0 | 102 | 32 | 2.5P | 12.5 | 10.0 | 3/4 |

| M17 | 1.5 | 102 | 32 | 2.5P | 12.5 | 10.0 | 4 |

| M18 | 1.5/2.0/2.5 | 112 | 37 | 2.5P | 14.0 | 11.2 | 4 |

| M20 | 1.5/2.0/2.5 | 112 | 37 | 2.5P | 14.0 | 11.2 | 4 |

| M22 | 1.5/2.0/2.5 | 118 | 38 | 2.5P | 16.0 | 12.5 | 4 |

| M24 | 1.5/2.0/3.0 | 130 | 45 | 2.5P | 18.0 | 14.0 | 4 |

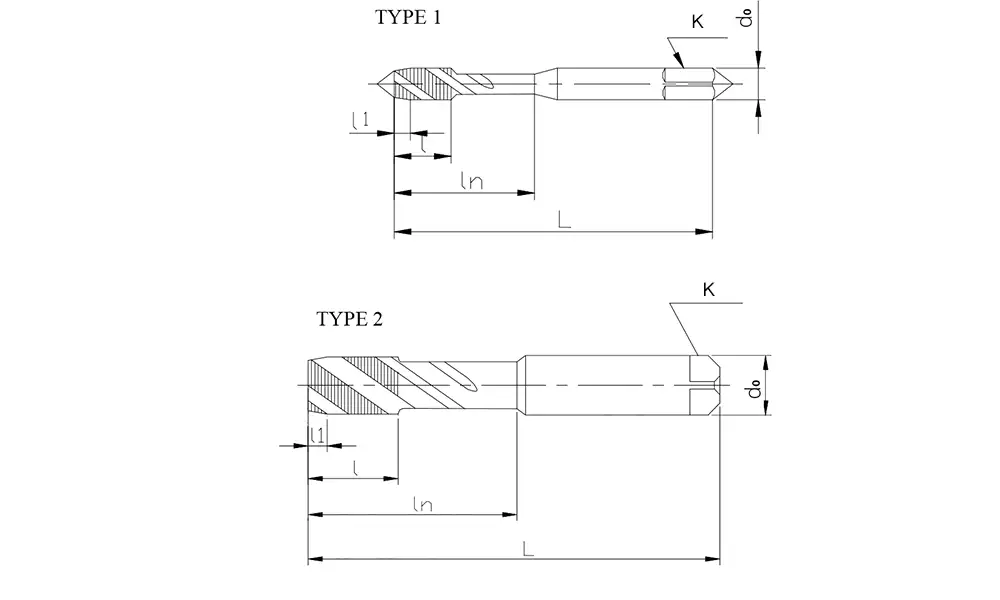

| Thread Size | TYPE | Pitch | L Overall length |

l Thread Length |

l1 Cutting Length |

ln Length to neck |

d₀ Shank diameter |

K Square size |

FLUTES |

| M3 | 1 | 0.35/0.5 | 48 | 6 | 2.5P | 16.5 | 3.15 | 2.5 | 3 |

| M4 | 1 | 0.5/0.7 | 53 | 8 | 2.5P | 19.5 | 4.0 | 3.15 | 3 |

| M5 | 1 | 0.5/0.8 | 58 | 9 | 2.5P | 23.5 | 5.0 | 4.0 | 3 |

| M6 | 1 | 0.5/0.75/1.0 | 66 | 11 | 2.5P | 29 | 6.3 | 5.0 | 3 |

| M7 | 2 | 0.75/1.0 | 66 | 11 | 2.5P | 30 | 7.1 | 5.6 | 3 |

| M8 | 2 | 1.0/1.25 | 72 | 13 | 2.5P | 35 | 8.0 | 6.3 | 3 |

| M10 | 2 | 1.0/1.25/1.5 | 80 | 16 | 2.5P | 39 | 10.0 | 8.0 | 3 |

| Thread Size | Pitch | L Overall length |

l Thread Length |

l1 Cutting Length |

d₀ Shank diameter |

K Square size |

FLUTES |

| M7 | 0.75/1.0 | 66 | 11 | 2.5P | 5.6 | 4.5 | 3 |

| M8 | 0.75/1.0/1.25 | 72 | 13 | 2.5P | 6.3 | 5.0 | 3 |

| M10 | 0.75/1.0/1.25/1.5 | 80 | 16 | 2.5P | 8.0 | 6.3 | 3 |

| M12 | 1.0/1.25/1.5/1.75 | 89 | 18 | 2.5P | 9.0 | 7.1 | 3 |

| M14 | 1.0/1.25/1.5/2.0 | 95 | 21 | 2.5P | 11.2 | 9.0 | 3/4 |

| M16 | 1.0/1.5/2.0 | 102 | 21 | 2.5P | 12.5 | 10.0 | 3/4 |

| M18 | 1.0/1.5/2.0/2.5 | 112 | 26 | 2.5P | 14.0 | 11.2 | 4 |

| M20 | 1.0/1.5/2.0/2.5 | 112 | 26 | 2.5P | 14.0 | 11.2 | 4 |

| M22 | 1.0/1.5/2.0/2.5 | 118 | 26 | 2.5P | 16.0 | 12.5 | 4 |

| M24 | 1.0/1.5/2.0/3.0 | 130 | 31 | 2.5P | 18.0 | 14.0 | 4 |

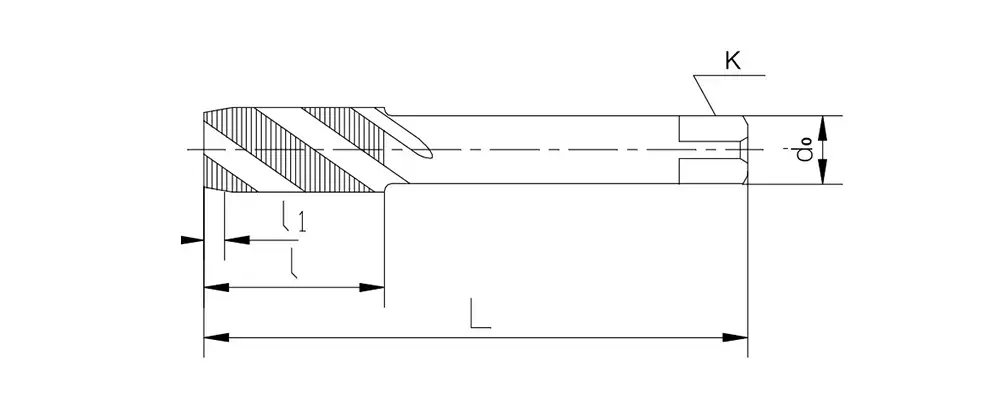

The helical flute design effectively lifts chips out of the hole during tapping, preventing chip clogging and reducing the risk of tap breakage.

Particularly well-suited for tapping blind holes because the spiral flutes direct chips upward and out of the hole, ensuring a clean cut and preventing damage to the threads.

Provides high-quality, precise threads with a clean finish due to the efficient removal of chips, reducing the chances of burr formation and thread distortion.

Suitable for a wide range of materials, including soft materials like aluminum, and harder materials like stainless steel, thanks to their ability to manage chip flow effectively.

The helical design reduces cutting forces during tapping, minimizing wear on the tap and allowing for smoother operation, especially in tough or sticky materials.

Due to efficient chip evacuation and reduced cutting forces, these taps generally have a longer lifespan compared to straight flute taps, making them more cost-effective over time.