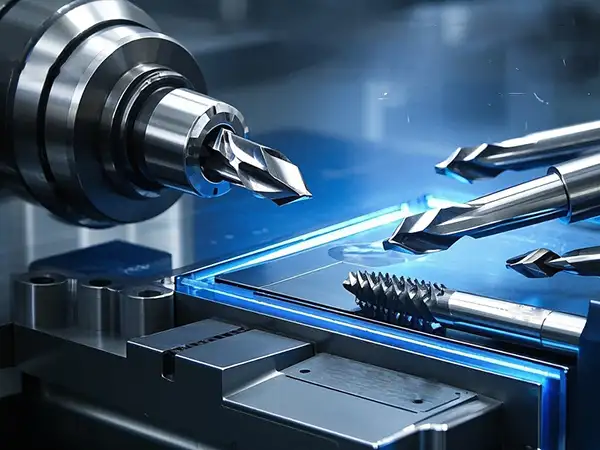

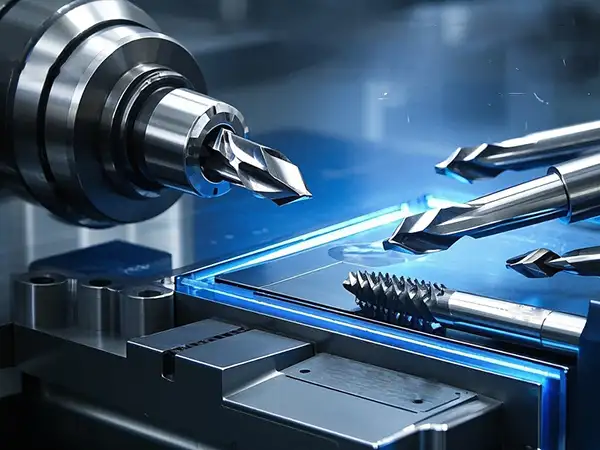

The automotive manufacturing industry has always had high demands on processing accuracy and efficiency, especially in thread processing. Threads are a key part in the connection of many automotive components, directly impacting the performance and safety of vehicles. In order to improve production efficiency and processing quality, an increasing number of automotive manufacturers are turning to high-performance cutting tools, such as CPM taps. This article will explore the application of CPM taps in automotive manufacturing, particularly how they effectively improve production efficiency and processing precision in factories like ours.

The engine is the heart of a car, and many components require internal threads for connections or assembly, such as cylinder heads, oil pans, and engine blocks. These parts are usually made of high-strength steel or aluminum alloys, which can cause traditional taps to wear out quickly during machining. CPM taps, with their superior wear resistance and thermal stability, ensure processing accuracy and prolong tool life, reducing downtime caused by tool wear.

There are numerous threaded connections in the automotive transmission system, such as gears, bearings, and various fasteners. These threads need to be highly precise to ensure the stable operation of the transmission system. The high-precision features of CPM taps play an important role in the machining of transmission system components, ensuring thread quality and preventing loosening or mismatch during assembly.

Modern vehicle body structures often use high-strength steel, aluminum alloys, or other lightweight materials. These materials tend to be hard, and ordinary taps may wear too quickly or cause unstable cutting, affecting processing results. CPM taps, with their high wear resistance and heat resistance, are ideal for processing these materials, ensuring high-precision thread processing without issues, thereby enhancing the overall strength of the body connections.

With the expansion of automotive production scales, many automotive components need to be produced in large quantities. Choosing the right thread processing tool becomes crucial. CPM taps, due to their long service life and high stability, effectively increase processing efficiency in mass production, reduce tool change frequency, lower production costs, and enhance overall production efficiency.

Today, most automotive manufacturers have adopted automated production lines to improve production speed and precision. In such production environments, CPM taps are able to withstand high loads and high speeds, ensuring continuous operation of the production line, reducing human intervention, and further improving production efficiency.

Despite the excellent performance of CPM taps in automotive manufacturing, there are still some challenges in practical application. For example, machining certain complex materials can lead to excessive tool wear, especially at high cutting speeds. To overcome these issues, manufacturers need to continuously optimize the material selection and coating technology of the taps to improve their adaptability to specific working conditions.

CPM taps, with their excellent wear resistance, high-temperature resistance, and processing accuracy, have been widely applied in the automotive manufacturing industry. From engines to body structures, transmission systems, and automated production lines, CPM taps play an irreplaceable role in the thread processing of various automotive components. For general hardware factories, using CPM taps not only improves processing accuracy and production efficiency but also greatly reduces tool change frequency, minimizes production downtime, and is an effective tool for enhancing overall production capacity and reducing production costs.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.