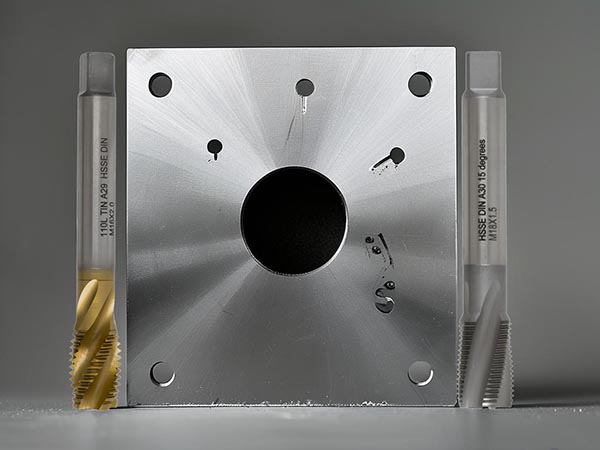

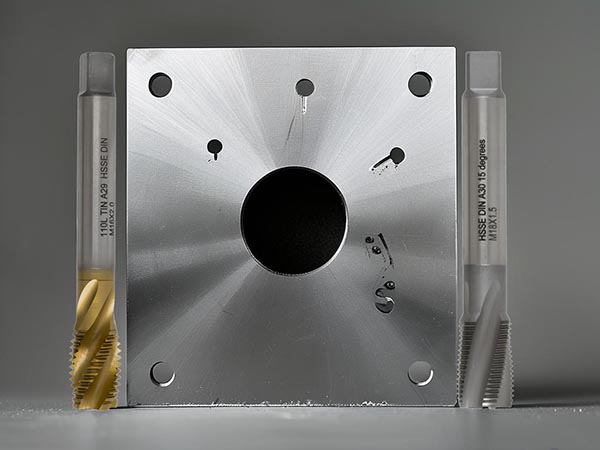

How to Choose the Right Tap Coating for Titanium Alloy Machining? A Practical Comparison Between TiAlN and AlCrN

Titanium alloys are increasingly used in aerospace and medical applications due to their exceptional strength-to-weight ratio. However, they remain notoriously difficult to machine, commonly causing severe tool wear and adhesion issues. As a core technology in titanium alloy tapping, coating selection has a direct impact on machining efficiency and cost control. Although both TiAlN and AlCrN belong to the nitride family, they differ fundamentally in microstructure and thermal response mechanisms. This article analyzes their atomic-level mechanisms, presents multi-dimensional performance testing, and compares real-world industrial applications to uncover the dynamic trade-offs in key metrics such as diffusion wear resistance, thermal stability, and interfacial adhesion strength—providing precise coating selection guidance for various machining scenarios.

| Comparison Aspect | TiAlN Coating (“Bulletproof Vest”) | AlCrN Coating (“Lubricated Armor”) |

|---|---|---|

| Best Application | Stable, continuous cutting | Interrupted cuts with potential chatter |

| Max Heat Resistance | 800°C (remains effective at red heat) | 650°C (risk of delamination under heat) |

| Cutting Characteristics | Requires reduced spindle speed | Allows higher feed rates |

| Maintenance Cost | ~30% more life after each regrind | Requires specialized equipment for recoat |

(A Quantitative Comparison Matrix)

| Evaluation Metric | TiAlN Score | AlCrN Score | Testing Method |

|---|---|---|---|

| Diffusion Wear Resistance | 92 | 88 | SEM + EDS Elemental Mapping |

| Adhesive Wear Resistance | 85 | 94 | Chip Morphology Classification |

| Thermal Stability | ★★★★★ | ★★★★☆ | Hardness Test After 30min @ 800°C |

| Coating Adhesion Strength | HV0.3 2800 | HV0.3 3200 | Nanoindentation |

| Recoating Compatibility | Up to 3 recoats | Requires substrate reprocessing | Secondary Deposition Adhesion Testing |

Choosing the right coating for titanium machining is a delicate balance between materials science and real-world engineering practice. TiAlN excels in continuous deep-hole operations thanks to its ability to form stable oxide layers at 800°C. AlCrN, by leveraging Cr’s inhibition of interfacial reactions, proves ideal for interrupted cutting tasks. With the advancement of nano-composite coatings and intelligent sensing technologies, traditional performance boundaries are being redefined. Decision-makers must consider machine rigidity, cooling methods, and production volumes as part of a holistic "substrate-coating-process" strategy. The future of coating technology lies in functional integration and intelligent responsiveness—paving new paths for efficient titanium machining.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.