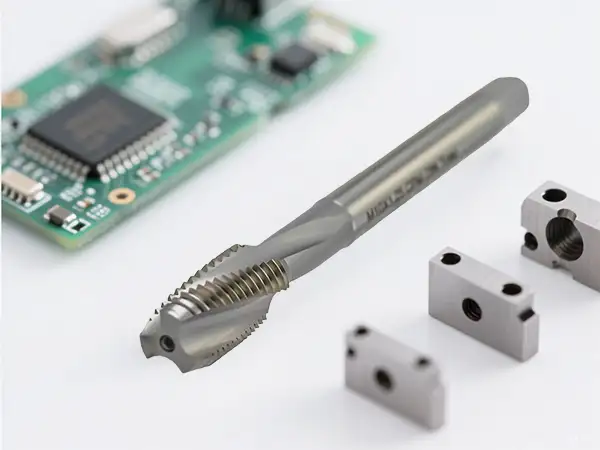

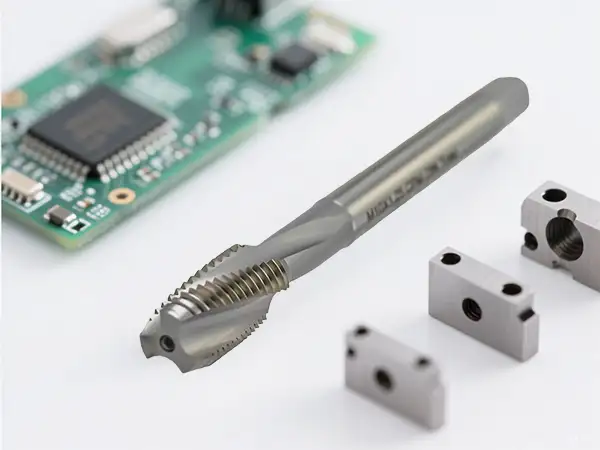

With the continuous advancement of electronic technology, various electronic devices are developing in the direction of smaller sizes and higher precision. Whether it's smartphones, televisions, computers, or home appliances, the components of these electronic products all rely on precision metal parts. Among these components, thread machining plays a crucial role in their production process. To ensure high-quality thread machining, CPM taps have become one of the preferred tools for many electronic product manufacturers. They not only improve machining efficiency but also ensure the accuracy and smoothness of threads.

Advantages of CPM Taps in the Electronics Industry

- Durability and Long Lifespan

In the electronics industry, many components require long periods of continuous work, especially in large-scale factories. If the tools wear out too quickly, it may result in downtime and increased tool replacement costs. Thanks to the superior materials and coatings, CPM taps can withstand extended high-intensity work, reducing tool replacement frequency and thus saving production costs.

- Thermal Stability and Resistance to Deformation

During machining, friction generates significant heat, especially when processing high-hardness materials. If the tool cannot withstand high temperatures well, it may lead to decreased thread accuracy or tool deformation. CPM taps maintain sharpness even at high temperatures, preventing thread damage and machining errors caused by heat. This thermal stability is especially beneficial when machining difficult materials such as alloys and stainless steel.

- High Precision Machining

In electronic products, particularly for circuit boards (PCBs) and miniature connectors, thread precision is critical. Threads that are too large or too small can affect the assembly precision of components, thereby impacting the functionality and performance of the product. CPM taps ensure that the machined threads have precise dimensions and smooth surfaces, eliminating errors during the machining process and improving overall production efficiency and product quality.

- Compatibility with Various Materials

Common machining materials in the electronics industry include aluminum alloys, stainless steel, copper alloys, etc. Traditional taps may not perform well when machining these hard materials and tend to wear out quickly. CPM taps, with their superior wear resistance and cutting performance, can work reliably with these hard materials, ensuring high machining quality.

Applications of CPM Taps

- PCB (Printed Circuit Board) Hole Machining

PCBs are one of the most common components in electronic devices. Particularly for products like smartphones and computers, their quality directly affects the functionality of the electronic device. CPM taps are typically used for thread machining in hole positions and blind holes on PCBs. Since PCB materials are often fragile, traditional machining methods may cause cracks or damage, but CPM taps can precisely machine the required threads while ensuring the board is not damaged during the process.

- Connector and Electronic Socket Thread Machining

Electronic connectors are widely used in communication devices, home appliances, automobiles, and other fields. To ensure that connectors fit tightly with other components, thread machining in electronic connectors requires very high precision. CPM taps ensure the smoothness and accuracy of the threads, thereby ensuring the proper functionality of the connectors.

- Precision Sensor Housings and Other Precision Parts

Many electronic products use small sensors and optoelectronic components, which typically require precise machining of their housings. To ensure that these housings fit tightly with other components, thread machining is usually required on hard metal materials. CPM taps, with their high hardness and long lifespan, can successfully machine these complex and hard materials.

- Automotive Electronics and Home Appliance Industry Applications

In the automotive electronics field, an increasing number of electronic components require precision thread machining, including dashboards, control systems, and other key parts. In the home appliance sector, internal and external threads in products like refrigerators and washing machines also require precise machining. CPM taps perform excellently in these high-precision applications, providing stable quality assurance.

CPM Tap Selection and Usage Tips

- Choosing the Right Coatings and Materials

Different electronic components and materials require different tap coatings. To improve machining efficiency, using coatings with high wear resistance (such as TiN or TiAlN coatings) can reduce wear and improve machining quality. In addition, selecting the appropriate CPM tap material (such as HSS-E or carbide) will help meet specific machining needs.

- Optimizing Cutting Parameters

During machining, adjusting cutting speed, feed rate, and cutting depth is crucial for improving the CPM tap's lifespan and machining quality. Excessive feed rate can lead to premature tool wear or poor surface quality, while a low cutting speed may reduce machining efficiency. Therefore, precise cutting parameter settings are essential for machining electronic products.

- Regular Maintenance and Inspection

To ensure that CPM taps maintain good cutting performance over time, regular inspection of wear status and cleaning of tool impurities is necessary. Regular maintenance can extend the lifespan of the taps and ensure consistent machining accuracy for electronic parts.

Conclusion: The Significance of CPM Taps in the Electronics Industry

As the demand for high-precision and high-efficiency production in the electronics industry continues to grow, CPM taps, with their advantages in wear resistance, thermal stability, and cutting precision, have become indispensable machining tools for many electronics manufacturers. Their wide application in PCB machining, connector manufacturing, sensor housings, and other fields has helped electronic product manufacturers reduce production costs and improve machining quality and efficiency. In the future, as technology continues to evolve, CPM taps will play an increasingly important role in the electronics industry, driving the sector toward more refined and automated manufacturing processes.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.