In-Depth Analysis of Solid Carbide Drills: A Dual Revolution in Precision Manufacturing and Global Trade

"When a solid carbide drill bit with a diameter of just 0.5mm is magnified under a microscope, its cutting-edge grain structure appears as tightly packed as a honeycomb, and its helical flute surface is as smooth as a mirror. This is the secret behind its ability to penetrate titanium alloys effortlessly at 30,000 RPM. As the 'ultimate tool' in modern precision manufacturing, the solid carbide drill achieves unparalleled rigidity and lifespan compared to traditional brazed drills through its 100% alloy substrate and nano-grade edge processing. From 0.1mm bone holes in minimally invasive medical devices to deep-hole machining in aerospace turbine blades, its performance limits are continuously redefining the precision boundaries of industrial manufacturing."

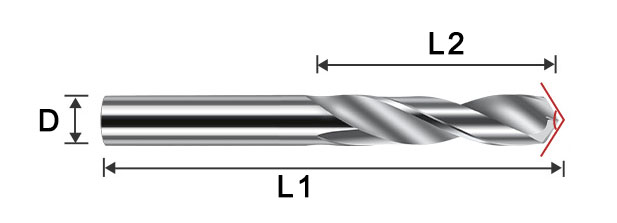

Sculpted from a Single Metal Block (vs. Brazed Drill: Like a Pencil Tip Attached to a Wooden Stick)

Ideal for Machining Tough Materials: Stainless Steel, Titanium Alloys, Carbon Fiber, etc.

Raw Material Cost Breakdown:

Tungsten Powder (68%) > Cobalt Powder (22%) > Sintering Energy Consumption (10%)

Price Comparison:

One High-Quality Drill ≈ 1g of Silver (Linked to Real-Time Precious Metal Market)

Sintering Analogy: Like Cooking Diamonds in a Pressure Cooker (1500°C + 200 Atmospheres)

Precision Control: Equivalent to Engraving a QR Code on a Strand of Hair (Edge Accuracy ≤ 0.005mm)

Look for "Carbide" Label (vs. Regular High-Speed Steel)

Premium Drill Features: Uniform Metallic Sheen (Inferior Products Show Spots or Pores)

Recommended Angles by Material:

Case Study: A Vietnamese Auto Parts Factory Increased Aluminum Machining Efficiency by 40% by Switching to 140° Drill Bits

Common Coating Properties Comparison:

Tip: For Sea Freight Exports, Choose Dual-Layer Coating for Extra Protection

Common Preferences by Region:

Beware of "Fully Ground" vs. "Semi-Ground" Manufacturing Differences (Check Edge Smoothness)

Essential Test Reports: Hardness Test HRC ≥ 90

Possible Cause: Excessive Speed (Tip: Machining Stainless Steel Requires Medium Speed, Like Driving at 60km/h)

Solution: Apply Canola Oil as a Temporary Substitute for Professional Cutting Fluids

Checklist:

Check Material Hardness – Harder Materials Require Harder Drills

Ensure Secure Clamping – Allowable Movement < 1mm

From ultra-fine grain control in the substrate material to 3μm-level cutting edge radius transitions, the technological breakthroughs of solid carbide drills are fundamentally a "dual-helix evolution" of materials science and precision machining. With the advancement of 5-axis simultaneous grinding technology and AI defect detection systems, these "metal scalpels" are redefining the possibilities of modern manufacturing.

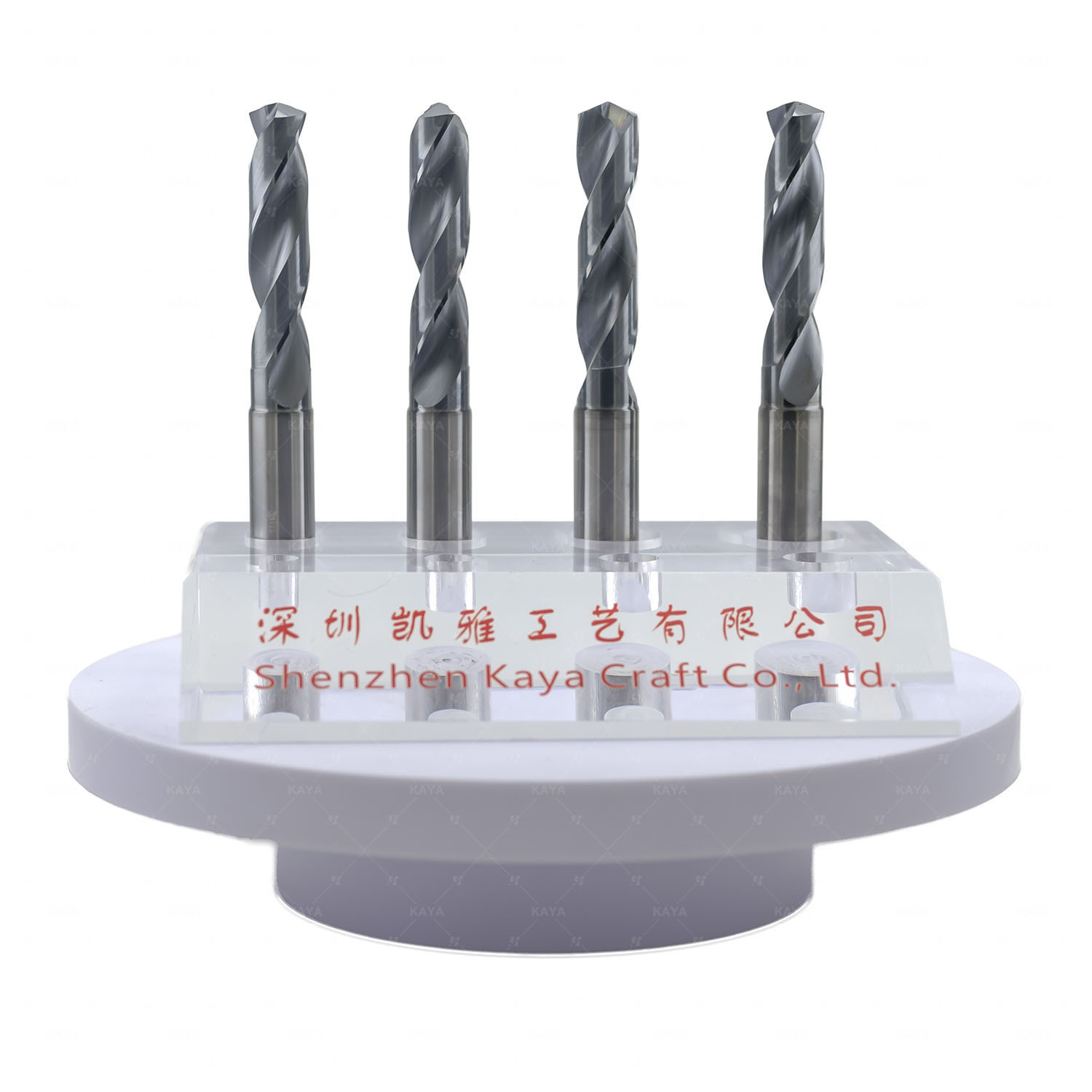

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.