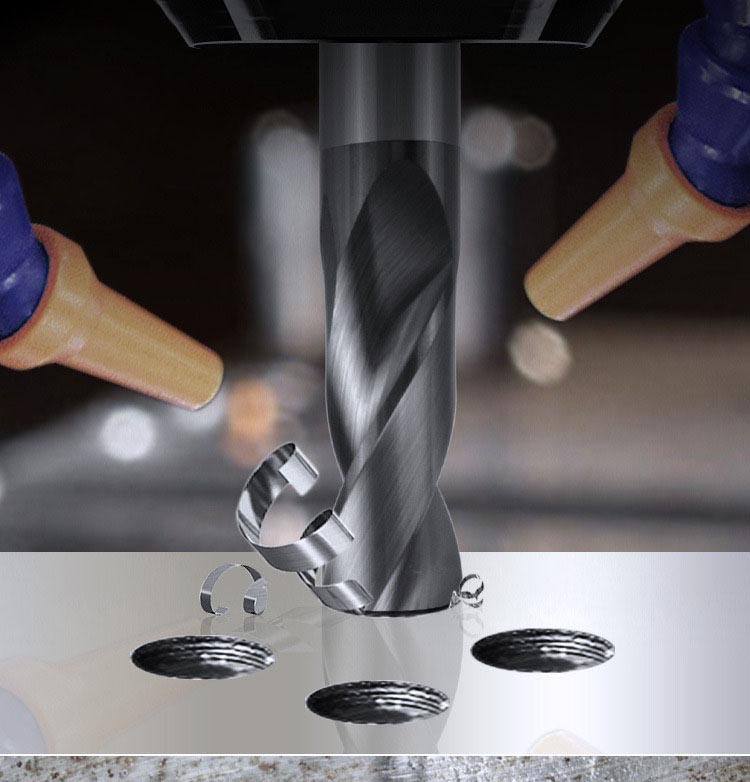

The Industry Truth About Tungsten Carbide Drills: The Underlying Logic Behind Continuous Global Procurement

For decision-makers in metalworking tool procurement, finding drills that withstand real-world workshop conditions is far more important than just comparing specifications. Let’s strip away the marketing fluff and get to the essence.

The Uncompromising DNA Code

Core Material: Tougher Than Diamond Yet More Practical

- Tungsten Steel Legion – Over 70% tungsten carbide (WC) forms an interlocked armor, achieving three times the hardness of hardened steel (Rockwell Hardness A 88-93).

- Cobalt-Based Binder – 6-12% cobalt acts like shock-absorbing foam, a golden ratio validated by ISO 513 testing in 2023.

- Special Additives – 0.5-2% tantalum carbide/titanium carbide to counteract the “acidic trap” encountered when drilling stainless steel.

Thermodynamic Adaptation of Advanced Coating Technologies

| Coating Type | Deposition Process | Application | Performance Improvement |

|---|

| TiAlN | Arc Ion Plating | High-temperature alloy machining | Tool life ↑ 320% |

| AlCrN | Magnetron Sputtering | Interrupted cutting of stainless steel | Surface roughness ↓ Ra 0.4 |

| Diamond Coating | CVD Method | Carbon fiber composites | Machining efficiency ↑ 700% |

|

Molecular-Level Truths Beyond Marketing Jargon

Tungsten Carbide Content ≠ Quality: Three Common Misconceptions in Global Procurement

- Correction: 82% WC may be inferior to 78% WC if cobalt distribution is uneven.

- Key Indicator: ISO 4505-certified porosity < A02 is more critical than mere composition ratios.

- Field Verification: Use a 30x magnifying glass to check the uniformity of WC grain distribution at the drill tip.

The Global Battle Over Cobalt Binders

- European Preference: 6-8% Co content + micron-level gradient sintering (suitable for high-precision CNC machines).

- Southeast Asian Solution: 10-12% Co + isostatic pressing (to handle workshop voltage fluctuations).

- American Innovation: 9% Co + nano-grain boundary diffusion technology (balancing impact resistance and wear resistance).

The Strategic Value of Special Additives

- Tantalum Carbide (TaC): Reduces acidic corrosion loss by 42% when machining stainless steel.

- Titanium Aluminum Nitride (TiAlN): Extends coating life threefold in high-temperature alloy drilling.

- Rare Earth Elements: The hidden force behind improved chip breaking efficiency in cast iron machining.

Workshop-Proven Performance

- ✓ Tough Cutting Power – Effortlessly handles HRC 50+ materials (Case study: A German automotive parts manufacturer reduced tool breakage by 63% when machining cast iron housings).

- ✓ Endurance King – Completed 500 continuous drill holes in a 24-hour aerospace bolt production line (with coolant testing).

- ✓ High-Temperature Immunity – Maintains sharpness at 800°C, outperforming high-speed steel drills that fail at 650°C (based on DIN 8039 thermal shock test data).

- ✓ Tool Change Revolution – A Vietnamese motorcycle parts factory saved 19 hours per month in machine setup time.

- ✓ Scrap Rate Eliminator – Improved machining yield of 316L stainless steel from 92% to 98% (verified by a Spanish food machinery manufacturer audit report).

- ✓ Energy Cost Magic – Maintains the same feed rate with 20% lower spindle speed (instant cost savings calculation: 11kW spindle × $0.15/kWh × ...).

Cross-Border Workshop Techniques

- ► Spark Identification – Genuine tungsten carbide produces short orange sparks; beware of long white sparks.

- ► Acoustic Detection – A steady "hissing" sound in aluminum machining is normal; high-pitched metal screeches indicate runout issues.

- ► Chip Analysis – Blue-violet chips in titanium machining suggest a perfect 0.1mm/tooth feed rate.

Field Reports from Global Production Lines

-

◉ The Precision Demands of Medical Devices

- Swiss Orthopedic Implant Manufacturing: 0.8mm micro-holes drilled continuously in titanium alloy 200 times, maintaining a ±0.003mm hole tolerance (ISO 2768-f compliant).

- Japanese Endoscope Instruments: Compared to Ti-coated drills, tool life when machining 316L stainless steel improved by 3.2 times (under NSF-certified coolant conditions).

- ◉ Extreme Challenges in the Energy Sector

- Norwegian Subsea Valve Machining: In a simulated sulfur-containing seawater environment, corrosion-resistant coated drills lasted 400% longer than standard models.

- Texas Shale Gas Drilling Equipment Maintenance: Drilling efficiency on HRC 55 wear-resistant plates increased by 70%, reducing per-unit machining costs from $4.20 to $1.70.

- ◉ Breaking Industry Bottlenecks

- Medical Devices: “0.5mm micro-drill hole diameter fluctuation < ±0.002mm on cobalt-chrome alloy” — Swiss orthopedic implant manufacturer.

- Energy Equipment: “Tool life still exceeds 400 hours in sulfur-rich conditions” — Norwegian subsea valve manufacturer.

- Consumer Electronics: “Burr control in magnesium alloy drilling meets VDE 0683 standards” — German connector giant.

- ◉ Unexpected Benefits for Procurement Decision-Makers

- ✓ U.S. Automotive Parts Manufacturer: Saved $45,000 annually in tooling management labor costs.

- ✓ Indian Die-Casting Factory: Reduced mold repair downtime by 62%.

- ✓ Brazilian Aerospace Tier-2 Supplier: Passed Nadcap tooling audit for the first time.

Conclusion

Our factory has been exporting drills for 16 years and knows that a great tool doesn’t need fancy words. The next time you face a tough machining challenge, try a real tungsten carbide drill—let the chips fly, and the veteran machinists in your workshop will tell you what “true toughness” really means.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.