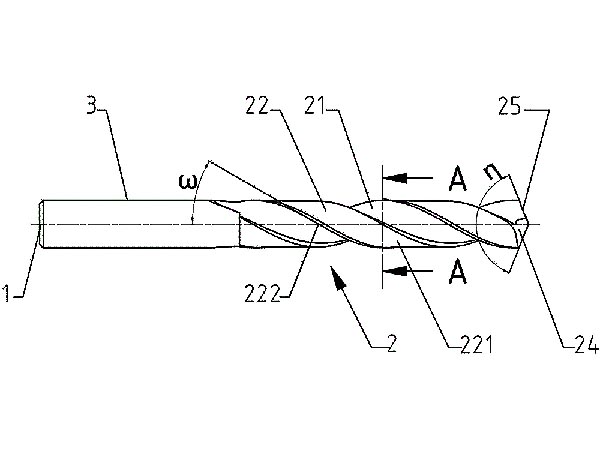

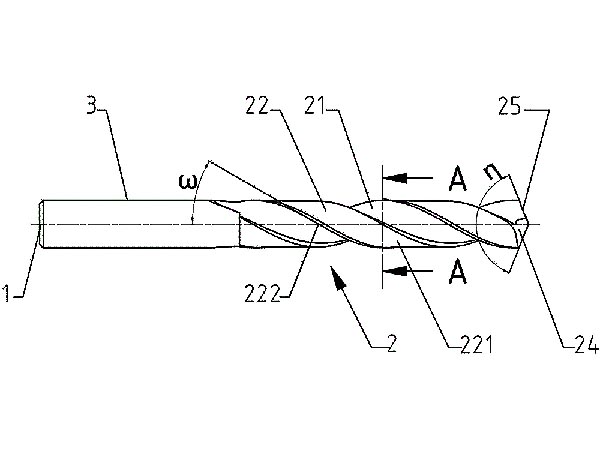

The twist drill bit consists of the following structural components:

The spiral flute of a twist drill bit is typically designed with two flutes, which help in effectively removing chips during the drilling process. The spiral angle usually ranges from 30° to 45°, optimizing cutting performance. The primary role of the spiral flute is to facilitate the evacuation of chips, preventing accumulation in the hole. This helps reduce cutting heat and improves overall cutting efficiency. Additionally, the spiral design enhances the stability of force transmission during cutting.

The drill tip is the front part of the twist drill, consisting of two cutting edges and a central point. The cutting edges are responsible for material removal, while the central point aids in positioning. The angle of the drill tip (commonly 118° or 135°) affects cutting performance. A smaller angle is suitable for softer materials, while a larger angle is better for harder materials. The design of the drill tip ensures accurate initial penetration and minimizes deflection.

The main cutting edges refer to the two cutting edges of the drill bit that directly engage with the material. They are typically angled with respect to the axis of the drill to optimize the cutting process. The shape and sharpness of the main cutting edges directly influence the cutting efficiency and the surface quality of the hole. Well-designed main cutting edges improve cutting efficiency and reduce cutting forces.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.