In-depth Technical White Paper on ISO 965 Thread Tolerance Standard: From Theory to Industrial Breakthroughs

The ISO 965 thread tolerance standard, a globally recognized framework in manufacturing, carries far greater technical depth than its dimensional codes suggest. In practice, enterprises often face the paradox of “compliant but failing”: a titanium alloy screw processed to 6H tolerance exhibits a 0.02 mm oversize in pitch diameter during assembly due to unaccounted low-temperature material rebound; or, using the standard three-wire method, a 15% misjudgment rate arises from neglecting the geometric coupling between thread pitch and wire diameter. These issues reveal broken links between material science, thermodynamics, and metrology in standard implementation. This paper goes beyond surface values—analyzing the physical basis of formulas, nanoscopic coating deformations, and nonlinear responses under extreme conditions—to uncover the full-spectrum technical logic behind ISO 965.

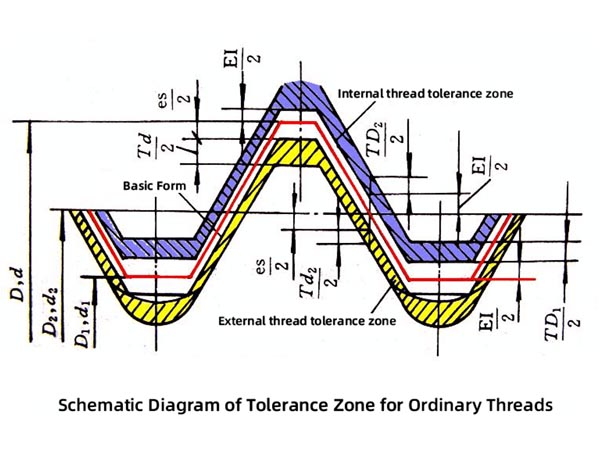

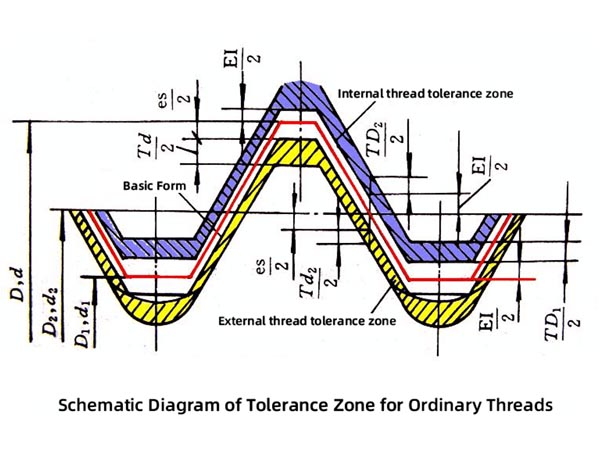

ISO 965 classifies tolerance into two key dimensions:

| Tolerance Grade | Recommended Tool Type | Key Machining Notes |

|---|---|---|

| 4H/4h | Micro-grain carbide thread milling cutter | Temperature-controlled workshop + vibration monitoring |

| 6H/6g | Cobalt HSS taps | Inspect wear every 200 pcs |

| 7H/7g | General-purpose HSS taps | Allow 10% overlap in tolerance zone |

| 8H/8h | Economy-coated tools | Increase pre-hole diameter by 0.05–0.1 mm |

In ISO 965-3’s recommended inspection methods, misapplication of wire size formulas is common:

Case – German-owned enterprise:

ISO 965 divides thread tolerances in the ratio: 60% pitch diameter + 30% pitch + 10% profile angle, based on:

T = 1.0 × (0.001×1.5 + 0.15×1.5² / 9.026) ≈ 0.038 mm

| Material | Temp Sensitivity (μm/°C·m) | Critical ΔT |

|---|---|---|

| Carbon Steel | 0.11 | ±8 °C |

| Stainless Steel | 0.18 | ±5 °C |

| Titanium Alloy | 0.07 | ±12 °C |

| Aluminum Alloy | 0.25 | ±3 °C |

Note: When ambient variation exceeds critical ΔT, ISO/TR 13908 compensation must be activated.

Solution: Build a coating compensation database

| Coating Type | Pitch Dia. Correction (μm) | Pitch Correction Coef. |

|---|---|---|

| TiN | +3~5 | 0.998 |

| TiCN | +5~8 | 0.995 |

| AlTiN | –2~+1 | 1.002 |

Japanese company case:

| Comparison Item | ISO 965-1 | ASME B1.13M | DIN 13-20 |

|---|---|---|---|

| Pitch dia. deviation | H: 0 to +μm | H: +12 μm start | H: +8 μm start |

| Crest truncation | Allows 1/8H | Strictly limited | Allows 1/6H |

| Temperature baseline | 20 ± 1 °C | Not specified | 23 ± 2 °C |

Case: M12 stainless screw exported to Germany

Achieving real-world implementation of ISO 965 requires moving beyond static tolerance interpretation to a dynamic technical ecosystem. From quantifying coating-induced micron-scale pitch deviations to predicting thermal expansion during ocean freight; from revolutionizing the three-wire method with quantum precision to integrating digital twins for tolerance pre-compensation—each aspect redefines the boundaries of “qualified.” In an era of global manufacturing, only by converting standards into material databases, intelligent inspection algorithms, and compensation models can compliance become a technical barrier. As thread accuracy enters the sub-micron arena, the ability to deeply decode ISO 965 is now the key to unlocking high-end supply chains.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.