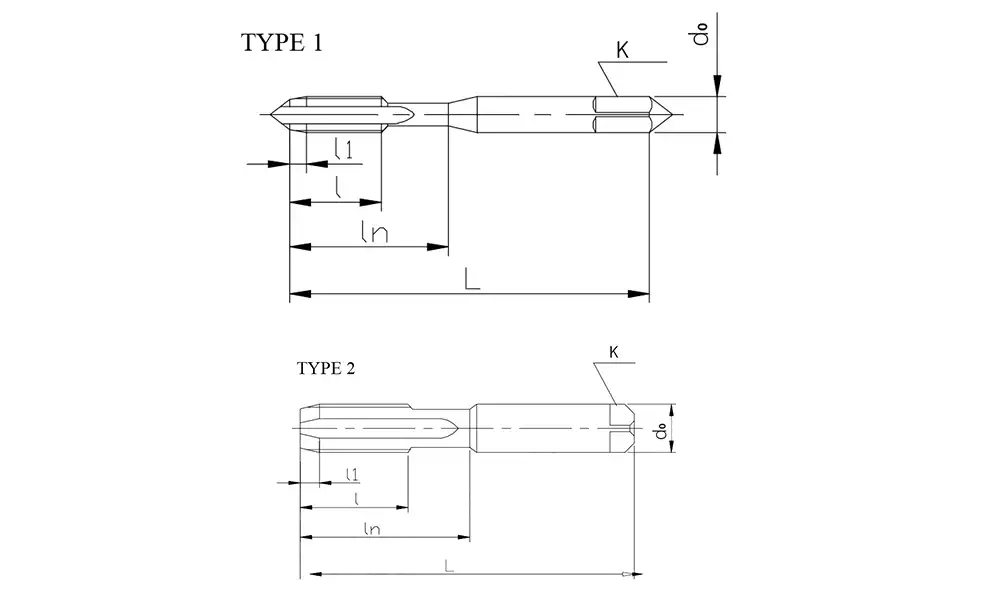

| Thread Size | TYPE | Pitch | L Overall length |

l Thread Length |

l1 Cutting Length |

ln Length to neck |

d₀ Shank diameter |

K Square size |

FLUTES |

| M3 | 1 | 0.35/0.5 | 48 | 11 | 4.5P | 16.5 | 3.15 | 2.5 | 3 |

| M3.5 | 1 | 0.35/0.6 | 50 | 13 | 4.5P | 18.5 | 3.55 | 2.8 | 3 |

| M4 | 1 | 0.5/0.7 | 53 | 13 | 4.5P | 19.5 | 4 | 3.15 | 3 |

| M4.5 | 1 | 0.5/0.75 | 53 | 13 | 4.5P | 19.5 | 4.5 | 3.55 | 3 |

| M5 | 1 | 0.5/0.8 | 58 | 16 | 4.5P | 23.5 | 5 | 4 | 3 |

| M5.5 | 1 | 0.5 | 62 | 17 | 4.5P | 23.5 | 5.6 | 4.5 | 3 |

| M6 | 1 | 0.5/0.75/1.0 | 66 | 19 | 4.5P | 29 | 6.3 | 5 | 3 |

| M7 | 2 | 0.75/1.0 | 66 | 19 | 4.5P | 30 | 7.1 | 5.6 | 3 |

| M8 | 2 | 0.5/0.75 | 66 | 19 | 4.5P | 32 | 8 | 6.3 | 3 |

| M8 | 2 | 1.0/1.25 | 72 | 22 | 4.5P | 35 | 8 | 6.3 | 3 |

| M9 | 2 | 0.75 | 66 | 19 | 4.5P | 33 | 9 | 7.1 | 3/4 |

| M9 | 2 | 1.0/1.25 | 72 | 22 | 4.5P | 36 | 9 | 7.1 | 3/4 |

| M10 | 2 | 0.75 | 73 | 20 | 4.5P | 35 | 10 | 8 | 3/4 |

| M10 | 2 | 1.0/1.25/1.5 | 80 | 24 | 4.5P | 39 | 10 | 8 | 3/4 |

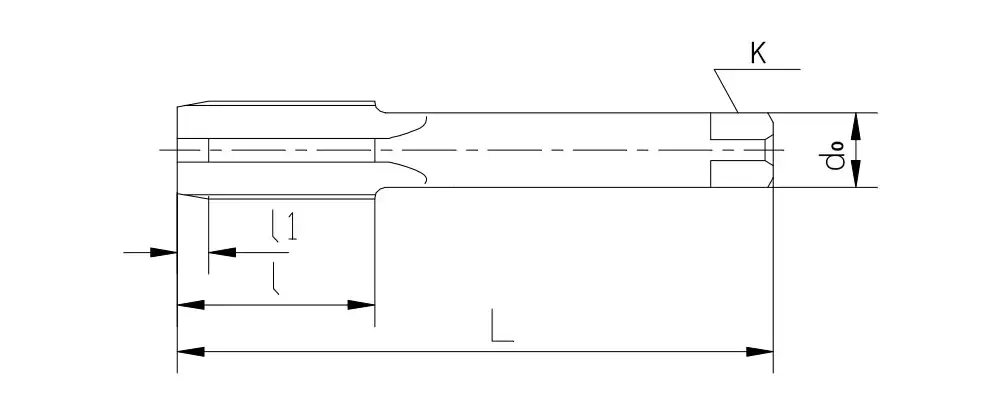

| Thread Size | Pitch | L Overall length |

l Thread Length |

l1 Cutting Length |

d₀ Shank diameter |

K Square size |

FLUTES |

| M7 | 0.75/1.0 | 66 | 19 | 4.5P | 5.6 | 4.5 | 3 |

| M8 | 0.75 | 66 | 19 | 4.5P | 6.3 | 5.0 | 3 |

| M8 | 1.0/1.25 | 72 | 22 | 4.5P | 6.3 | 5.0 | 3 |

| M9 | 0.75 | 66 | 19 | 4.5P | 7.1 | 5.6 | 3/4 |

| M9 | 1.0/1.25 | 72 | 22 | 4.5P | 7.1 | 5.6 | 3/4 |

| M10 | 0.75 | 73 | 20 | 4.5P | 8.0 | 6.3 | 3/4 |

| M10 | 1.0/1.25/1.5 | 80 | 24 | 4.5P | 8.0 | 6.3 | 3/4 |

| M11 | 0.75/1.0 | 80 | 22 | 4.5P | 8.0 | 6.3 | 4 |

| M11 | 1.5 | 85 | 25 | 4.5P | 8.0 | 6.3 | 4 |

| M12 | 1.0 | 80 | 22 | 4.5P | 9.0 | 7.1 | 4 |

| M12 | 1.25/1.5/1.75 | 89 | 29 | 4.5P | 9.0 | 7.1 | 4 |

| M14 | 1.0 | 87 | 22 | 4.5P | 11.2 | 9.0 | 4 |

| M14 | 1.25/1.5/2.0 | 95 | 30 | 4.5P | 11.2 | 9.0 | 4 |

| M15 | 1.5 | 95 | 30 | 4.5P | 11.2 | 9.0 | 4 |

| M16 | 1.0 | 92 | 22 | 4.5P | 12.5 | 10.0 | 4 |

| M16 | 1.5/2.0 | 102 | 32 | 4.5P | 12.5 | 10.0 | 4 |

| M17 | 1.5 | 102 | 32 | 4.5P | 12.5 | 10.0 | 4 |

| M18 | 1.0 | 97 | 22 | 4.5P | 14.0 | 11.2 | 4 |

| M18 | 1.5/2.0/2.5 | 112 | 37 | 4.5P | 14.0 | 11.2 | 4 |

| M20 | 1.0 | 102 | 22 | 4.5P | 14.0 | 11.2 | 4 |

| M20 | 1.5/2.0/2.5 | 112 | 37 | 4.5P | 14.0 | 11.2 | 4 |

| M22 | 1.0 | 109 | 24 | 4.5P | 16.0 | 12.5 | 4 |

| M22 | 1.5/2.0/2.5 | 118 | 38 | 4.5P | 16.0 | 12.5 | 4 |

| M24 | 1.0 | 114 | 24 | 4.5P | 18.0 | 14.0 | 4 |

| M24 | 1.5/2.0/3.0 | 130 | 45 | 4.5P | 18.0 | 14.0 | 4 |

| M27 | 2.0/3.0 | 135 | 45 | 4.5P | 20.0 | 16.0 | 4 |

| M30 | 3.5 | 138 | 48 | 4.5P | 20.0 | 16.0 | 4 |

| M33 | 3.0/3.5 | 151 | 50 | 4.5P | 22.4 | 18.0 | 6 |

| M36 | 4.0 | 162 | 56 | 4.5P | 25.0 | 20.0 | 6 |

| M39 | 3.0/4.0 | 170 | 59 | 4.5P | 28.0 | 22.4 | 6 |

| M42 | 4.5 | 170 | 59 | 4.5P | 28.0 | 22.4 | 6 |

| M45 | 4.5 | 187 | 66 | 4.5P | 31.5 | 25.0 | 6 |

| M48 | 5.0 | 187 | 67 | 4.5P | 31.5 | 25.0 | 6 |

The straightforward design leads to lower manufacturing costs and easier production and maintenance, making them ideal for high-volume production.

Suitable for a wide range of materials, including soft materials (such as aluminum and copper) and harder materials (such as steel), and performs well in general tapping tasks.

Particularly effective for tapping through-holes, as the chips are efficiently ejected downwards through the straight flutes, ensuring clean threads.

Provides stable cutting performance with uniform cutting force across the tool, suitable for moderate-speed cutting.

The absence of helical flutes results in a more rigid and robust tool, capable of withstanding higher cutting forces, making it suitable for harder materials.

The simple design facilitates easier alignment and centering, making them suitable for manual or machine tapping, especially in applications requiring precise alignment and perpendicular tapping.