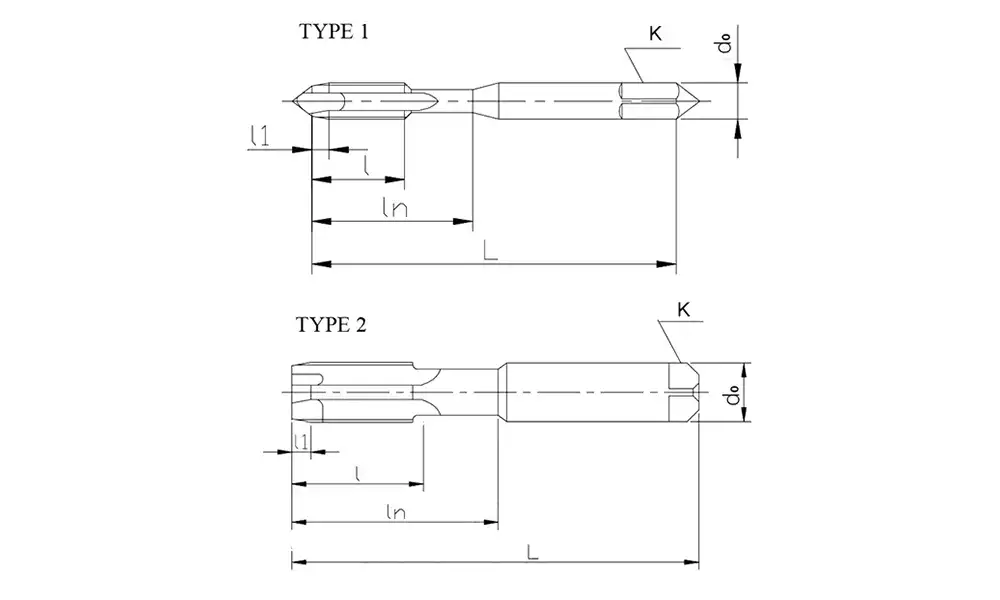

| Thread Size | TYPE | Pitch | L Overall length |

l Thread Length |

l1 Cutting Length |

ln Length to neck |

d₀ Shank diameter |

K Square size |

FLUTES |

| M3 | 1 | 0.35/0.5 | 48 | 11 | 5.5P | 16.5 | 3.15 | 2.5 | 3 |

| M3.5 | 1 | 0.35/0.6 | 50 | 13 | 5.5P | 18.5 | 3.55 | 2.8 | 3 |

| M4 | 1 | 0.5/0.7 | 53 | 13 | 5.5P | 19.5 | 4.0 | 3.15 | 3 |

| M4.5 | 1 | 0.5/0.75 | 53 | 13 | 5.5P | 19.5 | 4.5 | 3.55 | 3 |

| M5 | 1 | 0.5/0.8 | 58 | 16 | 5.5P | 23.5 | 5.0 | 4.0 | 3 |

| M5.5 | 1 | 0.5 | 62 | 17 | 5.5P | 23.5 | 5.6 | 4.5 | 3 |

| M6 | 1 | 0.5/0.75/1.0 | 66 | 19 | 5.5P | 29 | 6.3 | 5.0 | 3 |

| M7 | 2 | 0.75/1.0 | 66 | 19 | 5.5P | 30 | 7.1 | 5.6 | 3 |

| M8 | 2 | 0.5/0.75 | 66 | 19 | 5.5P | 32 | 8.0 | 6.3 | 3 |

| M8 | 2 | 1.0/1.25 | 72 | 22 | 5.5P | 35 | 8.0 | 6.3 | 3 |

| M9 | 2 | 0.75 | 66 | 19 | 5.5P | 33 | 9.0 | 7.1 | 3 |

| M9 | 2 | 1.0/1.25 | 72 | 22 | 5.5P | 36 | 9.0 | 7.1 | 3 |

| M10 | 2 | 0.75 | 73 | 20 | 5.5P | 35 | 10.0 | 8.0 | 3 |

| M10 | 2 | 1.0/1.25/1.5 | 80 | 24 | 5.5P | 39 | 10.0 | 8.0 | 3 |

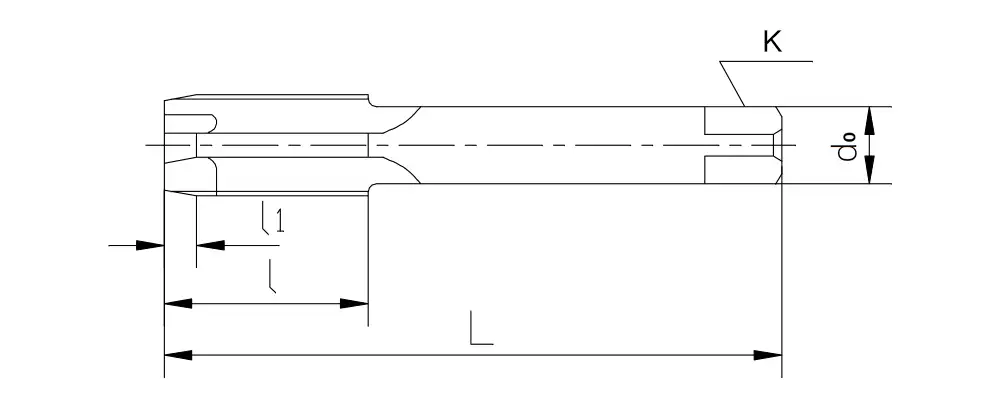

| Thread Size | Pitch | L Overall length |

l Thread Length |

l1 Cutting Length |

d₀ Shank diameter |

K Square size |

FLUTES |

| M7 | 0.75/1.0 | 66 | 19 | 5.5P | 5.6 | 4.5 | 3 |

| M8 | 0.75 | 66 | 19 | 5.5P | 6.3 | 5.0 | 3 |

| M8 | 1.0/1.25 | 72 | 22 | 5.5P | 6.3 | 5.0 | 3 |

| M9 | 0.75 | 66 | 19 | 5.5P | 7.1 | 5.6 | 3 |

| M9 | 1.0/1.25 | 72 | 22 | 5.5P | 7.1 | 5.6 | 3 |

| M10 | 0.75 | 73 | 20 | 5.5P | 8.0 | 6.3 | 3 |

| M10 | 1.0/1.25/1.5 | 80 | 24 | 5.5P | 8.0 | 6.3 | 3 |

| M11 | 0.75/1.0 | 80 | 22 | 5.5P | 8.0 | 6.3 | 3 |

| M11 | 1.5 | 85 | 25 | 5.5P | 8.0 | 6.3 | 3 |

| M12 | 1.0 | 80 | 22 | 5.5P | 9.0 | 7.1 | 3 |

| M12 | 1.25/1.5/1.75 | 89 | 29 | 5.5P | 9.0 | 7.1 | 3 |

| M14 | 1.0 | 87 | 22 | 5.5P | 11.2 | 9.0 | 4 |

| M14 | 1.25/1.5/2.0 | 95 | 30 | 5.5P | 11.2 | 9.0 | 4 |

| M16 | 1.0 | 92 | 22 | 5.5P | 12.5 | 10.0 | 4 |

| M16 | 1.5/2.0 | 102 | 32 | 5.5P | 12.5 | 10.0 | 4 |

| M18 | 1.0 | 97 | 22 | 5.5P | 14.0 | 11.2 | 4 |

| M18 | 1.5/2.0/2.5 | 112 | 37 | 5.5P | 14.0 | 11.2 | 4 |

| M20 | 1.0 | 102 | 22 | 5.5P | 14.0 | 11.2 | 4 |

| M20 | 1.5/2.0/2.5 | 112 | 37 | 5.5P | 14.0 | 11.2 | 4 |

| M22 | 1.5/2.0/2.5 | 118 | 38 | 5.5P | 16.0 | 12.5 | 4 |

| M24 | 1.5/2.0/3.0 | 130 | 45 | 5.5P | 18.0 | 14.0 | 4 |

The spiral point (or chisel point) design directs chips forward into the flutes, enhancing the removal of chips from the hole and reducing the risk of clogging.

Particularly effective for tapping through-holes as the chips are pushed out of the hole, preventing them from accumulating and ensuring smooth cutting.

The design minimizes friction and cutting force by directing the cutting action forward, making the tapping process smoother and less taxing on the tool and machine.

Provides high-quality threads with a clean finish due to efficient chip removal, which helps avoid thread damage and burr formation.

The reduced friction and efficient chip removal contribute to longer tool life, as the tap experiences less wear and tear during operation.

Suitable for a wide range of materials, including metals like steel, aluminum, and brass, as well as plastics, thanks to their efficient chip management and cutting performance.