The Enduring Power of High-Speed Steel (HSS) Cutting Tools: Technology Principles and Business Value in Precision Machining

In the ongoing wave of technological evolution in the field of precision machining, High-Speed Steel (HSS) cutting tools have retained an unshakable strategic position. According to the Global Cutting Tools Market White Paper, HSS tools have continued to grow at a compound annual rate of 4.3% over the past decade, even amidst the rapid adoption of carbide. The core value of HSS is evolving from being a “basic tool” to a “specialized solution.” From micro-thread repair in automotive manufacturing to fine finishing of complex aerospace components, HSS tools form a “resilient defense line” in precision machining through their unique material properties—especially in high-temperature, impact-heavy, and customized applications. This seemingly traditional material is continuously transcending its physical limits through technological innovation, meeting the modern industry's demand for a stringent balance between cost, efficiency, and reliability.

The Enduring Competitiveness of HSS Tools: Deep Dive into Technology and Commercial Impact

| Application Area | HSS Market Share | Key Use Cases | Carbide Market Share | Core Substitutability Factor |

|---|---|---|---|---|

| General Cutting Tools | 32% | General machining, maintenance | 58% | Cost-performance advantage |

| Tapping Tools | 58% | Thread repair in automotive/aerospace | 22% | Superior impact resistance |

| Drilling Tools | 49% | Multi-material stack drilling, cross holes | 37% | Adaptability to harsh conditions |

| Milling Tools | 27% | Mold finishing, thin-walled parts | 63% | Customization flexibility |

| Broaches/Reamers | 41% | Batch hole finishing, tight tolerances | 46% | Dimensional stability |

According to the Cutting Tool Engineering 2023 report, HSS still holds 32% of the global market, and up to 58% in tapping and drilling categories.

(Metallurgical Interpretation for General Audience)

| Metric | HSS Tools | Carbide Tools | Advantage Ratio |

|---|---|---|---|

| Tap breakage rate | 12% | 53% | 4.4× |

| Tool breakage recovery cost | $3.2 | $27.5 | 8.6× |

| Emergency sourcing time | 3 days | 21 days | 7× |

(Thermal Imaging Analysis from the Shop Floor)

| Material Type | Ideal Temp Range | Temp-Related Issue | Ideal Use Case | Critical Failure Temp |

|---|---|---|---|---|

| High-Speed Steel | 550–620°C | Matrix softening above 650°C | Aluminum, titanium alloys | 720°C |

| Carbide | 800–1000°C | Chip build-up below 500°C | Cast iron, hardened steel | 1200°C |

| Carbon Tool Steel | 200–300°C | Rapid softening beyond 350°C | Wood, plastic | 450°C |

| Ceramic Tools | 1100–1300°C | Micro-chipping from thermal shock | Superalloy finishing | 1400°C |

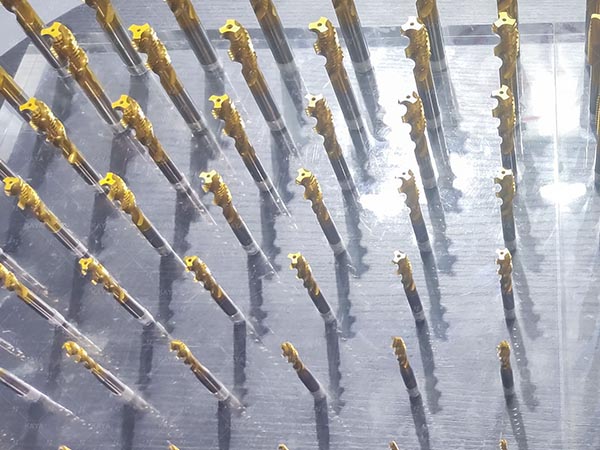

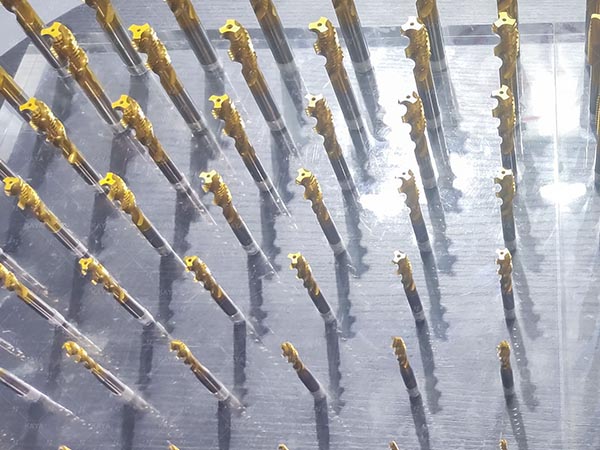

| Coating Type | Application | Tool Life Boost | Example Case |

|---|---|---|---|

| TiN | General steel | +30–50% | Valve components (India) |

| AlCrN | High-temp alloys | +70–90% | Aero engine repair (Russia) |

| DLC | Non-ferrous metals | +120–150% | Medical device machining (Germany) |

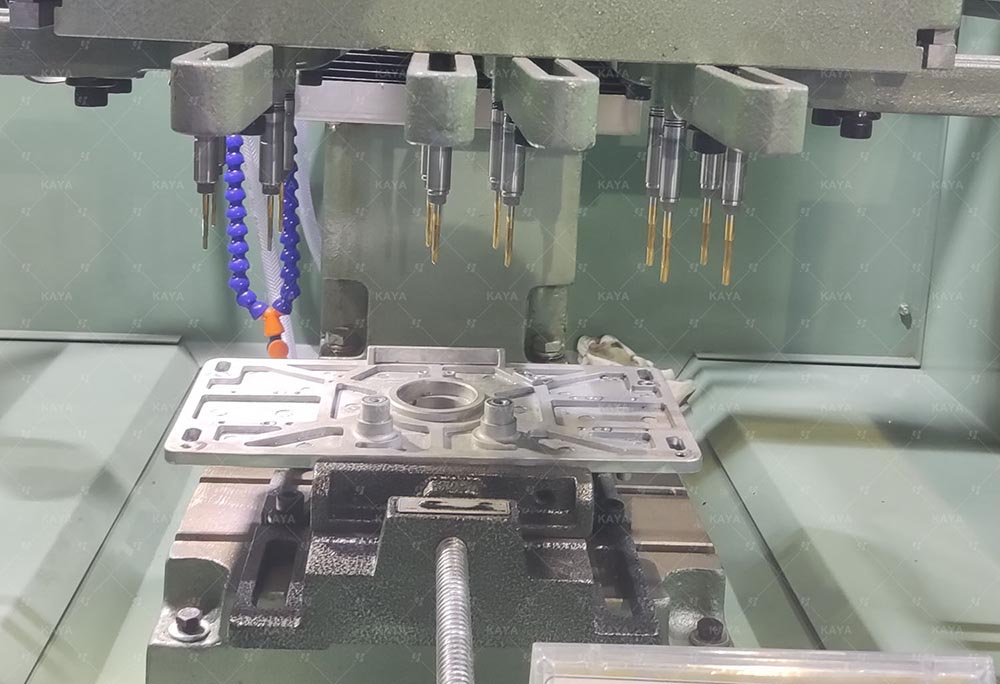

A hardware plant in Pakistan used HSS drills + minimum quantity lubrication (MQL) to solve BUE in stainless steel drilling, improving productivity by 40%.

| Region | Common Need | Recommended Solution |

|---|---|---|

| Middle East | High-temperature machining | M42 cobalt + AlCrN coating |

| Southeast Asia | Anti-rust in high humidity | Steam-oxidized HSS |

| Europe | Eco-compliance | Cadmium-free plated HSS |

| Machining Scenario | Suggested Tool Type | Cost Saving Method |

|---|---|---|

| Stainless steel finishing | HSSE with Ti coating | Extend tool change intervals |

| High-volume aluminum | Basic HSS with oxide finish | Lower unit tool cost |

| General repair workshops | Economy-grade HSS | Regrind and reuse |

The sustained vitality of HSS cutting tools lies in their deep-rooted alignment with industrial realities:

On the micro-scale, the synergy between carbides and steel matrix grants superior impact resistance.

On the thermal level, the precise “red hardness window” allows efficient processing of temperature-sensitive materials.

Commercially, flexible production systems adapt seamlessly to a fragmented global supply chain.

Today, as additive manufacturing and smart coatings converge, HSS tools are breaking through traditional boundaries—expanding into advanced fields like precision machining and green manufacturing. This century-old material platform continues to prove that true industrial competitiveness stems from a profound understanding of physical principles and systemic innovation.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.

We like to do design according to all the customers' requirements, or offer them our new designs. With strong OEM/ODM capabilities, we can fill your sourcing demands.